- Intern (m/f/d) in Battery Technology – Dry Coating & Powder Processing

- Machine and systems operator – “Slurry-production” (m/f/d)

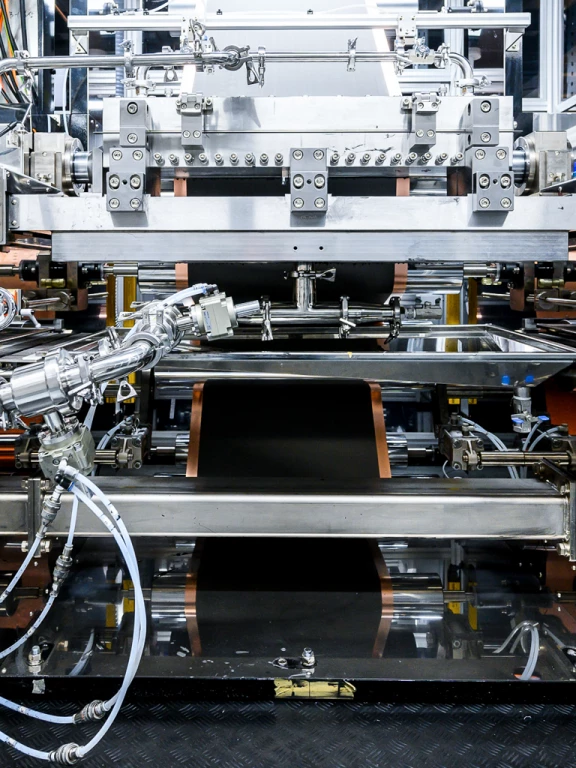

- Machine and systems operator – “Coating system” (m/f/d)

In today's world, energy is a very valuable resource that must be used responsibly and carefully. Therefore, the UniverCell website is available in an energy-saving version.

The brighter an OLED (Organic Light Emitting Diode) panel shines, the more energy must flow through the individual subpixels. This also applies the other way around: Dark colors require significantly less energy in practice and depending on the display model.

Imagine a manufacturer with a thriving business which produces safe and powerful battery systems for specific, advanced applications in its own module production. However, due to high demand and limited own production capacities, it needs a second source – one that is fast, reliable, and at least equally good. All of this while the big suppliers are focused on the automotive sector. Well, this is where we come into play.

First, we demonstrate the quality of our coating based on the desired recipe with a number of lab tests and pilot runs. After we have met the specified quality standards and have improved our processes, we transition to production and start to ramp up the production output. Our proven QA process ensures the required quality standards at all times – and protects the intellectual property of our clients. Furthermore, we constantly optimize our processes in order to strengthen the competitive advantages.

Continuous and intermittent coating, Coating speeds of up to 60 m/min, Double-sided coating in one step, Variable coating widths and loads, Inline coating weight controll wet and dry, Samespot metrology, Inline coat thickness measurement, Camera-monitored fault detection, Polypropylene and magnetic filter systems, 800 mm calander rollers, calendering speeds of up to 120 m/min, Heated rolls, Web edge control, Anti-wrinkle systems, Cutting machines