- Intern (m/f/d) in Battery Technology – Dry Coating & Powder Processing

- Machine and systems operator – “Slurry-production” (m/f/d)

- Machine and systems operator – “Coating system” (m/f/d)

In today's world, energy is a very valuable resource that must be used responsibly and carefully. Therefore, the UniverCell website is available in an energy-saving version.

The brighter an OLED (Organic Light Emitting Diode) panel shines, the more energy must flow through the individual subpixels. This also applies the other way around: Dark colors require significantly less energy in practice and depending on the display model.

Duration: 3 months / Full-time

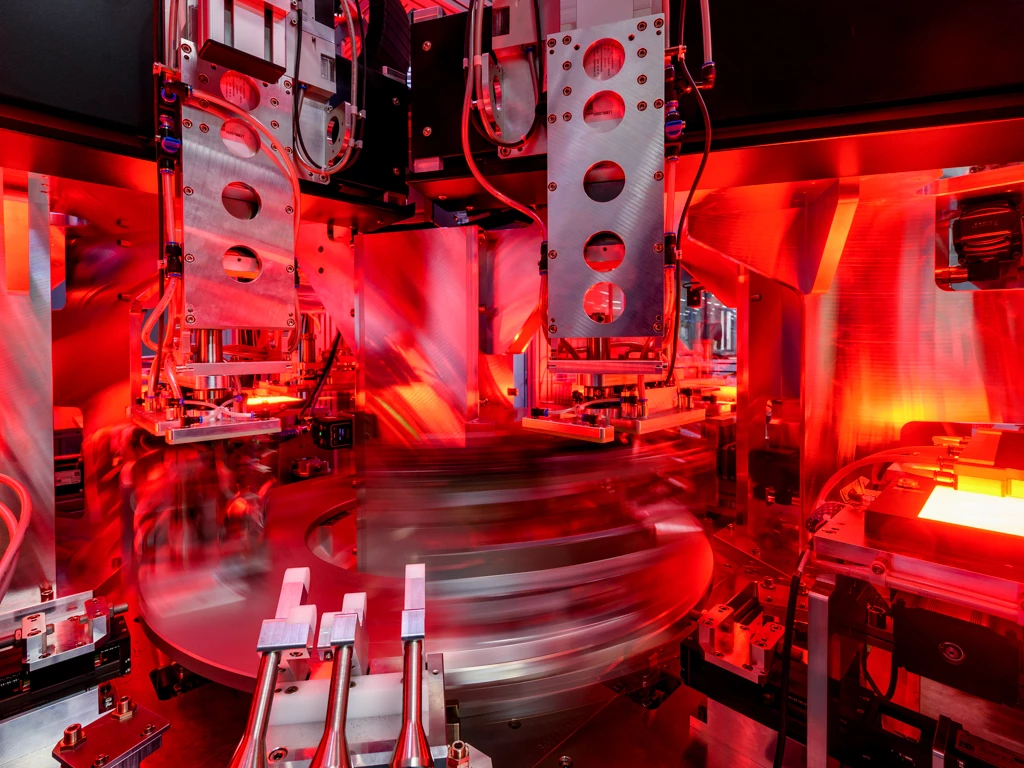

We offer an exciting internship in the field of electrode manufacturing for lithium-ion batteries, with a focus on dry coating as an innovative and sustainable process technology.

The internship focuses on investigating and further developing dry coating as an alternative to conventional wet coating of battery electrodes. A key component of the work is the production and processing of active material powders, which are subsequently converted into electrode films. The influence of various process parameters on the structure, mechanical stability, and electrochemical performance of the resulting electrodes will be analyzed. The goal is to gain an in-depth understanding of the relationships between powder properties, process conditions, and electrode structure in order to reliably assess and further develop the potential of dry coating for sustainable battery technologies.

UniverCell produces electrodes and cells based on lithium-ion technology for batteries in Germany. With everything we do, we make sustainable energy usable and develop highest-quality energy storage systems with innovative technology and maximum performance. Our products are used in aerospace, medical products and other areas where the highest quality and performance are required.

Your responsibilities

• Planning and execution of experiments for the production and characterization of powders for dry coating

• Investigation of powder properties (e.g. flowability and particle size) as a function of manufacturing parameters

• Processing of the produced powders into electrode films

• Analysis of the physical and electrochemical properties of the resulting electrodes

Your Profile

• Initial experience working in a laboratory environment, ideally with a background in electrochemistry

• Studies in chemical engineering, chemistry, industrial chemistry, or materials science

• Hands-on mentality and enthusiasm for both practical and analytical work

• Independent, responsible working style and strong analytical thinking skills

• Team player with openness to exchanging ideas

Vera Schloen

Commercial Employee – Financial Accounting (m/f/d)

Full-time – Flintbek

Chemical Laboratory Technician (m/f/d)

Part-Time – Flintbek

Maintenance Technician – Machinery and Building Services (m/f/d)

Full-Time – Flintbek and Russee

Mechatronics Technician – Maintenance (m/f/d)

Full-Time – Flintbek and Russee

Machine and systems operator – “Coating system” (m/f/d)

Flintbek

Machine and systems operator – “Slurry-production” (m/f/d)

Flintbek